SoliFuse channel letter 3D printing solutions, 3D letter generating software included for FREE:

Speed X1: 600×600×120mm

Speed X2: 900×900×120mm

Speed X3: 1350×900×120mm

Three models, all equiped with dual extruders

Speed X1: 600×600×120mm / 23.6×23.6×4.7 inches

Speed X2: 900×900×120mm / 35.4×35.4×4.7 inches

Speed X3: 1350×900×120mm / 53.2×35.4×4.7 inches

3D printing LED channel letters at 31mm³/s extrusion speed, two times faster than competing products on the market.

Speed Series adopts our leading DualDrive high-extruding-speed print head and powerful motion system, making it the fastest LED channel letter 3D printer on the market.

Easily making common used LED channel letters

It’s easy to define the light transmision area of a channel letter return by 3D printing lighttight or translucent filaments at certain heights of it.

Below are three channel letters 3D printed with lighttight white filament and translucent white filament, assembled with cutted acrylic sheets or liquid acrylic.

Face-Lit, Back-Lit and Face/Back-Lit LED channel letters ↓

3D printing & acrylic panels

3D print the channels, assemble them with laser cutted or CNC milled acrylic panels.

3D Printing & Liquid Acrylic Craft

Making thin typeface or intricate pattern signages will become your forte in business.

Mirror the letters, Generate a rib

Mirror the channels and 3D print them face down. Save your time for placing the channels on the glass.

Small letters, Thin typefaces, Complex patterns

Just pour the liquid acrylic into the 3D printed channels, leave all the issues related to complexity to our 3D printer.

Curing on the build plate

Put the build plate into a curing machine without removing the 3D printed channels on it.

Seamless workflow, simple and efficient.

3D Print the Channels and Face/Backing in One Piece

Not just 3D print the channel, you can also print the face or backing together with the channel, with various style combinations.

Backing and Channel in one piece

Get a ready-to-use backing and chennel right out of the printer.

Generate 3D Printing File from a 2D Pattern

Using Speed Series channel letter 3D printers, you don’t need to design 3D models.

We provide a free and easy-to-use 3D printing software FormLetter.

Import the vector file into our FormLetter software, and generate the 3D printing gcode file with just a click.

Filament Detection

If the filament runs out or is broken, the Speed Series channel letter 3D printers will automatically pause printing and wait for further processing.

Auto-Leveling

The Speed Series channel letter 3D printers adopts a 36 points fully automatic leveling function, which ensures successful printing and easy start-up.

Auto-Changing Filament

Speed Series can automatically change filament as you have set in the FormLetter software, two-color printing is easy as a click.

Two-in One-out Dual Color Print

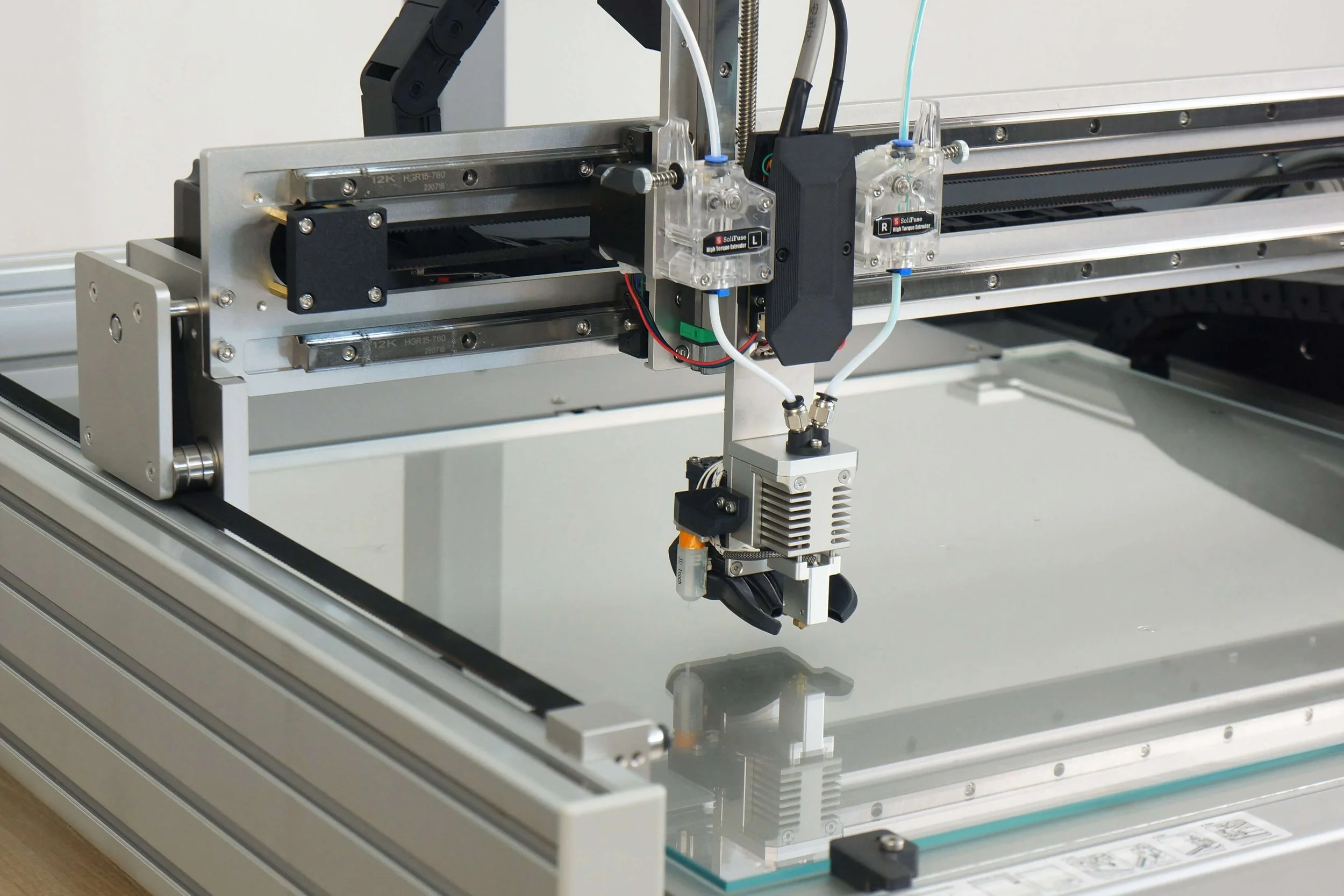

Speed Series adopts a two-filament-in, one-nozzle-out print head.

Our special filament runner design makes sure a nice and clean filament switch.

Dual Gear Filament Driving System

In the print head, there are two high torque feeding gears driving each filament, the large feeding force ensures 2.5 times fast extruding speed than a normal print head.

High Extruding Speed

The print head is equipped with a powerful and efficient heating system that makes high-speed plastic extruding happen.

Dual Linear Guides X-Gantry

To ensure rigidity of the Z axis module at high speed movement, we applied two linear guides for the X axis gantry.

Powerful Motion System

Speed Series adopts a high torque motion system which provides powerful and stable driving torque even at a high moving speed.

-

3D Print LED Channel Letter

-

Triditional LED Channel Letter

Exceptional Fivefold Profit Growth

Significant reduction in machines investment, materials cost and running cost

Labor-saving

3D printing LED channel letter is a simple production process without manually processing the stripes which save labor.

Lower materials cost

To make a 3D printed illuminated letter return, all the material you need is only the plastic filament, no other ingredients are needed, and almost no materials are wasted.

Less investment

3D printing channel letter returns will save the cost of buying the expensive bending machines, welding machines, and polishing machines, even save more.

Lower inventory

Using a 3D printer will get the freedom of return style and get rid of the limitation of conventional stripes. It will greatly reduce material inventory.

Consult an expert.

Want to know more about our products? Please don’t hesitate to leave a message.

Specifications

GENERAL

Build Volume

Speed X1: 600×600×120mm / 23.6×23.6×4.7 inches

Speed X2: 900×900×120mm / 35.4×35.4×4.7 inches

Speed X3: 1350×900×120mm / 53.2×35.4×4.7 inches

Technology

FFF (Fused Filament Fabrication)

Feeding Method

Two filaments in, one nozzle out

Print Head

HES Technology (High Extruding Speed Print Head)

Nozzle Temperature

260℃

Build Platform Temperature

80°C

Nozzle Diameter

0.6 mm

Layer Height

0.2~0.3 mm

Leveling Method

Auto calibration

Build Platform

Removable glass platform

HARDWARE

Data Transmission

Flash drive

Motion Controller

ARM Cortex-M4 120 MHz FPU

Motion Drive System

57mm step motors motion system

Screen

12864 Mono LCD screen

Internal Storage

8G

Filament Sensor

Yes (Automatically pause printing when the filaments run out)

POWER SUPPLY

Power Supply Input

100-130V or 200-230V AC, 50/ 60 Hz (Power supply UL certified)

Power

Speed X1: 800W

Speed X2: 2100W

Speed X3: 3100W

FILAMENT

Filament Diameter

1.75mm

Filament Type

PEA, PES filament

Third-party Filament

Available

SOFTWARE

Software

FormLetter

Input Format

SVG

Output Format

DXF format file for cutting machines

Operating System

Win 10

PACKAGING

What is in the box

1. Speed X1 3D Printer ×1

2. Spool Holder Kit ×1

3. Removable Build Plate ×1

4. Starter Kit ×1 (Including a set of hexagonal wrenches, U disk ×1, scraper ×1, offset socket wrench ×1)