About Us

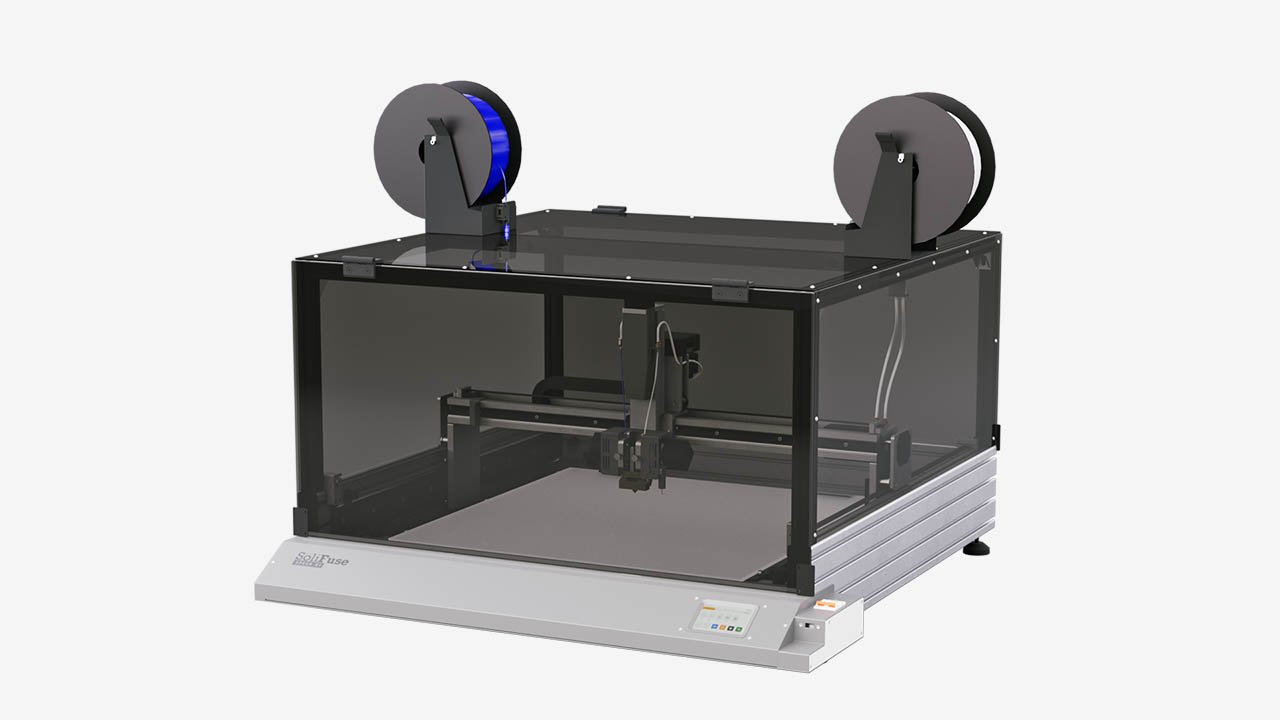

SoliFuse focuses on developing and producing 3D printing solutions for making LED channel letters, which are used as an alternative to channel letter benders. The solution includes channel letter 3D printers, 3D printing software, and special channel letter filaments.

SoliFuse is related to the Mankati 3D printer, both from Hydrogen Flow 3D.

The company started the research and development of FFF technology in 2013 and has accumulated nine years in FFF technology. These accumulations have made the SoliFuse luminous letter 3D printing solution a leading edge at the beginning of entering the market.

SoliFuse's brand mission is to bring infinite creativity to brand recognition.

Company Timeline

2022

Launch the Speed X1 3D printing solution in the oversea market

We are now expanding in the oversea market, aiming the revolution of making channel letters. Welcome any conversation about it.

2021

Release the channel letter 3D printing solution in the Chinese mainland market

After the Alpha and Beta test, we provide our channel letter 3D printer to our angel customers in China in March and officially release it in July. Within half a year, we achieved the most astonishing growth of a new product in our history.

2020

Establishing a new BU and a new brand “SoliFuse”, aiming the revolution in the sign industry

We noticed the needs and pain points in the channel letter processing technic, and assessed the technical and service accumulations of our company, we decided to enter this market. So we establish a new BU and brand for it, in the meantime, start the 3D printing solution R&D works.

2019

Launch 3D printing service for small batch production

We R&D the large volume 3D printer series by ourselves for our in-house 3D printing production business, targeting rapid manufacturing of small-batch end-use parts. By the end of 2019, we reach six tons of 3D printing parts production.

2018

Imagine bigger, Print bigger

We released E360 in 2018, which has a build volume of 360×360×300mm and is also targeted for 3D printing engineering plastics. It’s a solid machine for heavy-duty 3D printing tasks.

2017

Expand in the North America and Europe markets

Benefit from the technical advantages, product strategy, and support services, we got a remarkable growth in the North America and EU markets.

2016

3D printing slicer and 3D printer cluster management: mWare software

mWare is a revolutionary software with intelligentized 3D model analysis engine, clients can prepare the 3D printing files with just 4 clicks, and slicing a 3D model can never be so easy. The built-in mRemote module empowers the management of multiple E180 3D printers just like using office 2D printers.

2015

Powerful and intelligent, E180 borns for 3D printing strengthen parts

We released E180 in 2015, the most competing professional-grade 3D printer for making functional parts. It was dedicated to high-strength plastics like PC, PA, and fiber-reinforced thermal plastics, etc.

2014

Fullscale XT Plus released, make it even better

Based on the successful Fullscale XT 3D printer, we brought it to the next level. With higher printing speed and nozzle temperature, Fullscale XT Plus is one of the most powerful machines in the US and EU markets at the same price.

2013

Fullscale XT launched

It all begins with the Ultimaker open source project. We enhance it and empower it, the dual print head and large build volume features make it a professional and reliable tool for office prototyping.